From months of heatwave to severe flooding, South Asia in 2022 has been living proof that climate change is causing increased likelihood of extreme weather events.

And that’s not to mention extreme flooding in America earlier in the year, or the heatwaves happening right now in the UK and across Europe, with unprecedented temperatures and forest fires across France, Portugal, Spain, and Greece.

We could go on.

It can be easy to ignore the headlines on climate impacts. That’s especially true in terms of responding as a business – it just doesn’t feel like it impacts our day-to-day work, if we aren’t living in the immediate area affected.

In reality that isn’t true.

In today’s globalised economy, events like this heatwave have profound implications that ripple far beyond South Asia and cause supply chain issues for businesses across the world.

And as these events become more and more common, supply chain disruptions will impact every industry and every business.

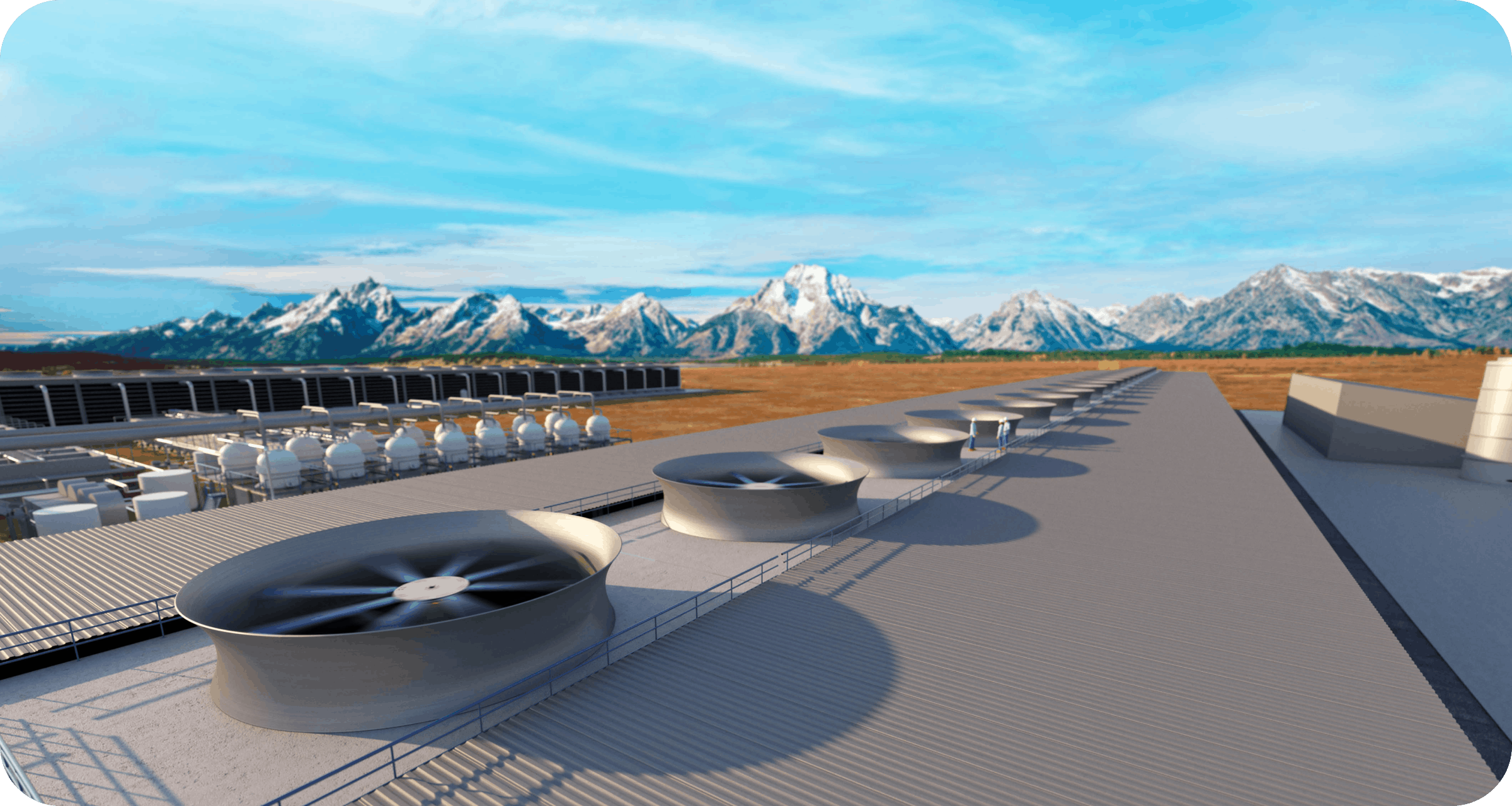

Air conditioning, power shortages, and wasted goods – what the heatwave means for India’s manufacturing industry

Let’s work through one example of the supply chain implications of this year’s prolonged heatwave in India: the impact of increased demand on energy on the manufacturing industry.

Step 1:

Due to the scorching heat, people have turned to air conditioning for comfort – even survival, in some cases. Air conditioning units are energy intensive, and energy demand has risen to an all-time high.

Subscribe for the latest insights into driving climate positivity

Step 2:

The increase in demand for energy has led to shortages, particularly in stocks of coal which became critically low early on in the heatwave. This meant that energy became very expensive in India, and that power outages became a regular occurrence.

Step 3:

Manufacturing businesses (amongst others, of course) rely heavily on energy, due to manufacturing machinery. India has a huge manufacturing industry, supplying parts to companies across the globe – in 2021, for instance, they exported machinery parts to a value of $1.06 billion to the UK, and $5.25 billion to the US.

Increased energy costs meant that some manufacturing businesses simply couldn’t afford to operate. And the power outages meant that machinery has been unable to be used for much of the working day over the period of the heatwave, which has spanned several months already.

Sandeep Mall’s engineering factory in Delhi, for instance, experienced power cuts of up to 14 hours every day. Every time a power cut started, their machines were interrupted and rejected the products they were working on – meaning the factory was wasting a lot of time and materials, and were able to produce much less than usual.

Step 4:

The global supply of manufactured goods is reduced and prices increase. In turn, this leads to increased running costs and/or shortages of supply for those businesses which use goods from India – which then creates further run-on impacts for other businesses in the supply chain. Mall’s factory, for instance, supplies parts for the aeronautics, automobile, mining and construction industries.

What’s the lesson for businesses?

That’s just one example of the impact of the heatwave on the global economy.

We could also talk about the shortage of wheat exports from India – adding to the lack of supply from Russia and Ukraine due to the war, and causing the global cost of wheat to increase to around $475 per tonne (compared to $260 in 2021).

But we won’t go into that now.

There are two key lessons to take from this.

1. Businesses need to adapt and innovate now to survive

As extreme weather events become more and more regular we’re going to see supply chain disruptions like those outlined in this article happening all the time – if this example wouldn’t affect you, another example will.

2. Businesses can be part of the solution

Businesses have huge influence in society and so they have a huge role to play in responding to climate change.

How?

By reducing your own carbon footprint, exploring ways to bring climate impact into your product and service, and contributing financially to rapid emissions reductions and carbon removal – including high-quality projects in India such as the Gold Standard certified Bagepalli CDM reforestation project working to reforest degraded agricultural land in the Chikkaballapur District of Karnataka.

Readers also liked

Readers also liked

Subscribe for emissions intelligence insights

Get the latest updates in the world of carbon tracking, accounting, reporting, and offsetting direct to your inbox.