Direct Air Capture – what is it? and how does it work?

With many different types of carbon projects out there, we know it can be overwhelming to understand what they do and evaluate which your company should buy carbon credits from.

To make the process a little easier, we’re publishing a series of explainers on the different project types. So far, we’ve explored afforestation, enhanced weathering, and ocean carbon removal.

Next up: Direct Air Capture – featuring example projects 1PointFive and Noya.

We’ll cover:

- How does Direct Air Capture work?

- The difference between Direct Air Capture and Carbon Capture and Storage

- What makes it exciting as a climate solution?

- And what’s holding it back?

- Should companies buy carbon credits in Direct Air Capture?

- Example project: scaling up supply with 1PointFive

- Example project: increasing affordability by using existing infrastructure with Noya

Subscribe for the latest insights into driving climate positivity

How does Direct Air Capture work?

Since the Industrial Revolution, we’ve pumped billions of tonnes of carbon dioxide into the air – over 34 billion tonnes every year, in fact.

Now, we need to get it out.

The IPCC has made it crystal clear that to have a chance of keeping within the acceptable level of 1.5 degrees of warming, we need to remove 10 billion tonnes of existing CO2 per year – alongside deep reductions to prevent further emissions as much as possible.

Direct Air Capture is one method for enabling this.

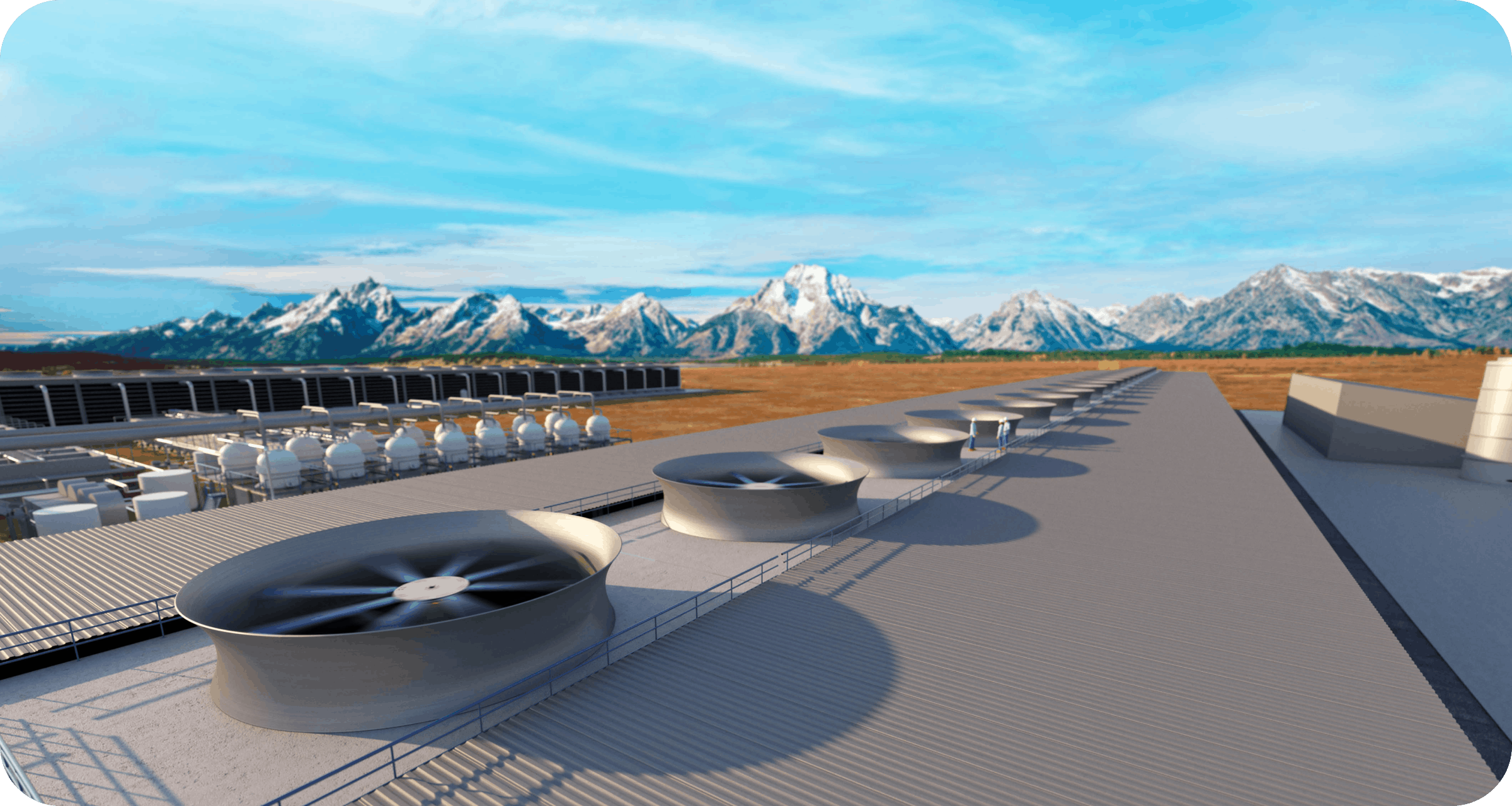

In Direct Air Capture (DAC), technology is combined with chemical processes to remove CO2 directly from the ambient air around us.

The process looks like this:

1. Air is drawn into the Direct Air Capture plant using large fans

2. Carbon dioxide is then extracted from the air. There are several ways to do this, with the most promising methods being:

- Solid DAC (S-DAC): air is passed through a filter which contains a solid adsorbent – a porous material that traps chemicals (in this case carbon) at its exposed surface, in a low temperature and high pressure environment. Once full, the CO2 is then desorbed from the filter in a high temperature and low pressure environment, producing a stream of pure CO2 gas. This need for constantly changing the pressure and temperature means that solid DAC requires a large amount of energy to work. This method is already in use, including by Climeworks.

- Liquid DAC (L-DAC): air is passed close to an alkali solution (aka liquid solvent) such as potassium hydroxide, causing the acidic CO2 in the air to react and form calcium carbonate salts in solution with water. The carbonate is then extracted from the liquid as small, solid pellets. Finally, the pellets are heated at a high temperature to release a stream of pure CO2 gas. This method is also already in use, including by Carbon Engineering.

- Electro swing: the change in environment from low temperature/high pressure for adsorption to high temperature/low pressure for desorption is known as a ‘swing cycle’, and because of the temperature difference it requires a high use of energy. But, these swing cycles can also be induced using electricity – known as electro swing cycles. Early-stage research and technology development is underway to explore whether this can be applied in Direct Air Capture, which could drastically reduce the amount of energy needed.

3. Finally, the air (minus CO2) is re-released back into the atmosphere.

A simplified diagram of the Direct Air Capture process, by the Carbon Engineering team.

A simplified diagram of the Direct Air Capture process, by the Carbon Engineering team.Subscribe for the latest insights into driving climate positivity

What happens with the captured carbon dioxide?

So, we’ve successfully removed carbon dioxide from the air.

Then what?

Well, there are two options:

- Use it: CO2 is used in various industries, including concrete, carbonated drinks, slaughterhouses, and agricultural fertilisers. In most of these use cases, the CO2 will eventually be re-released into the atmosphere (concrete being the exception).

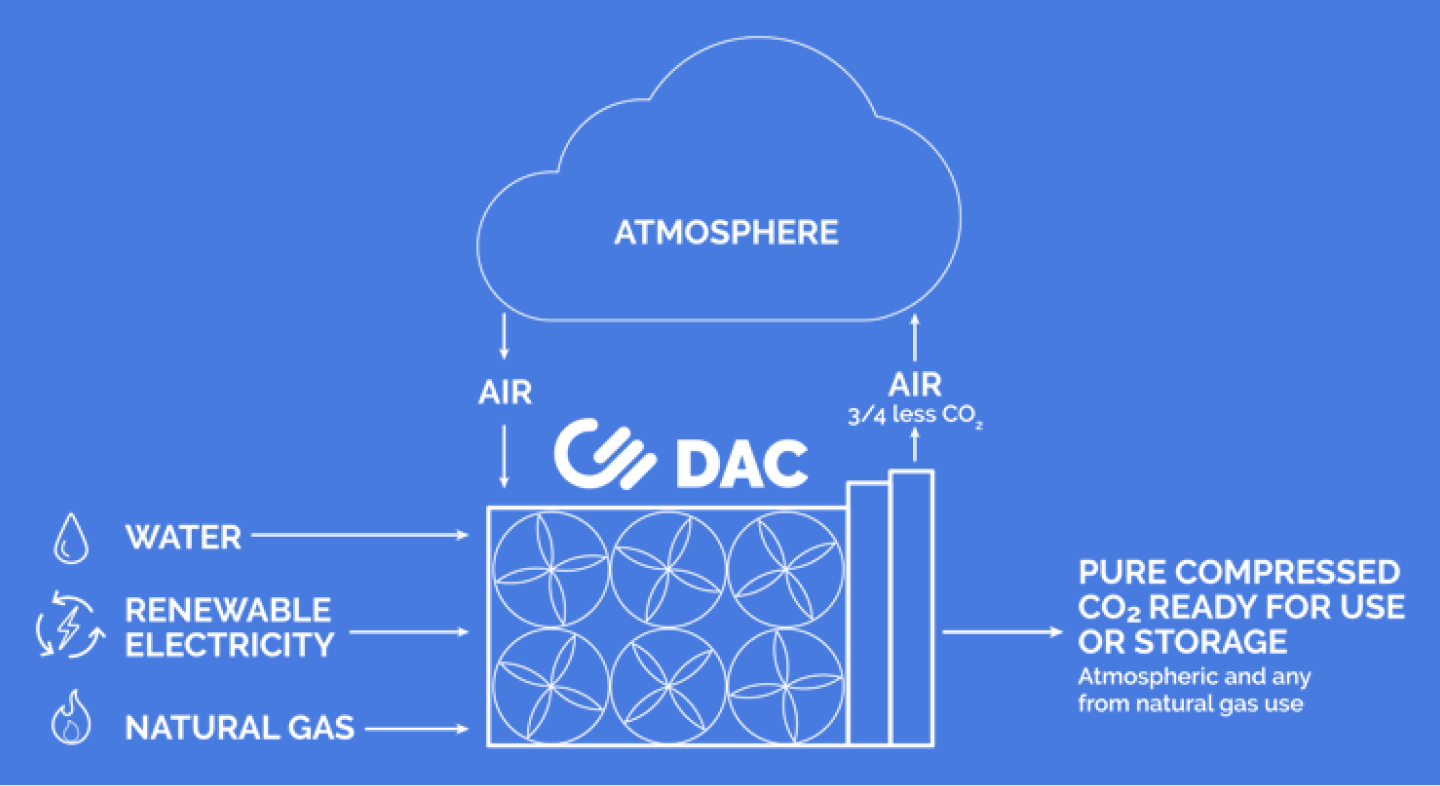

- Store it: alternatively, the CO2 can be stored to prevent it being returned to the atmosphere – creating a form of permanent carbon removal. Direct Air Capture can be combined with geological storage, where CO2 is injected deep underground where it is permanently trapped through geological sequestration. This is sometimes referred to as Direct Air Carbon Capture and Storage (DACCS).

Diagram by 1PointFive, showing how injection wells are used to transport CO₂ deep underground where it will be permanently stored.

Diagram by 1PointFive, showing how injection wells are used to transport CO₂ deep underground where it will be permanently stored.An FAQ: Is Direct Air Capture the same as Carbon Capture and Storage?

Nope!

Carbon Capture and Storage (CCS) and Direct Air Capture (DAC) are, understandably, often mixed up. But, what is the difference between the two?

In Carbon Capture and Storage projects, carbon emissions are captured at their source – for instance the carbon emitted through burning fossil fuels at power plants, or through industrial processes at manufacturing facilities (e.g. steel or cement). Similarly to DAC, the technology relies on chemical processes to extract the carbon dioxide from the exhaust gases produced. But, unlike DAC, the technology is retrofitted onto existing infrastructure to capture carbon at source e.g. the chimney of a power plant.

So, the big difference between Direct Air Capture and Carbon Capture and Storage is:

- Direct Air Capture is a carbon removal technique, actively removing existing carbon emissions from the atmosphere

- Carbon Capture and Storage is an emissions avoidance/reduction technique, preventing additional carbon emissions from entering the atmosphere from fossil fuel plants, industrial processes etc.

What makes Direct Air Capture exciting as a climate solution?

As we mentioned at the start of this article, we desperately need to remove existing carbon emissions from the atmosphere ASAP – at a rate of 10 billion tonnes per year.

But, we don’t currently have the means to reach that goal.

At the start of 2022 the amount of CO2 we’d ever removed from the atmosphere totalled less than 10,000 tonnes. We need to be doing that a million times over, every year.

There are several technologies and techniques in development for increasing our capacity for carbon removal, and Direct Air Capture is one of them.

DAC is particularly exciting because:

- Permanent removal: when combined with long-term storage (such as the geological storage outlined above), Direct Air Capture offers a way to take CO2 out of the atmosphere for good, ensuring it can never be re-released.

- Location agnostic: CO2 is in the air, everywhere, which means that in theory Direct Air Capture plants could be located absolutely anywhere in the world – which gives it huge potential to scale up and remove vast amounts of CO2.

- Low land use: DAC plants are also efficient in terms of the space and land required to remove CO2. One DAC plant uses the same space that a forest of 200 trees would, but the DAC plant removes 1,000 times more CO2 than the trees would over the space of a year. Again, this means that there’s huge potential to scale up the availability of DAC to remove huge amounts of carbon (data from Climeworks).

- Legislative backing: there’s also growing political backing for Direct Air Capture which should help to drive it forward, as governments are seeing the huge potential it could hold to scale up carbon removal and help them meet their climate targets. For instance, the US committed $12 million towards the development of DAC technology in 2021.

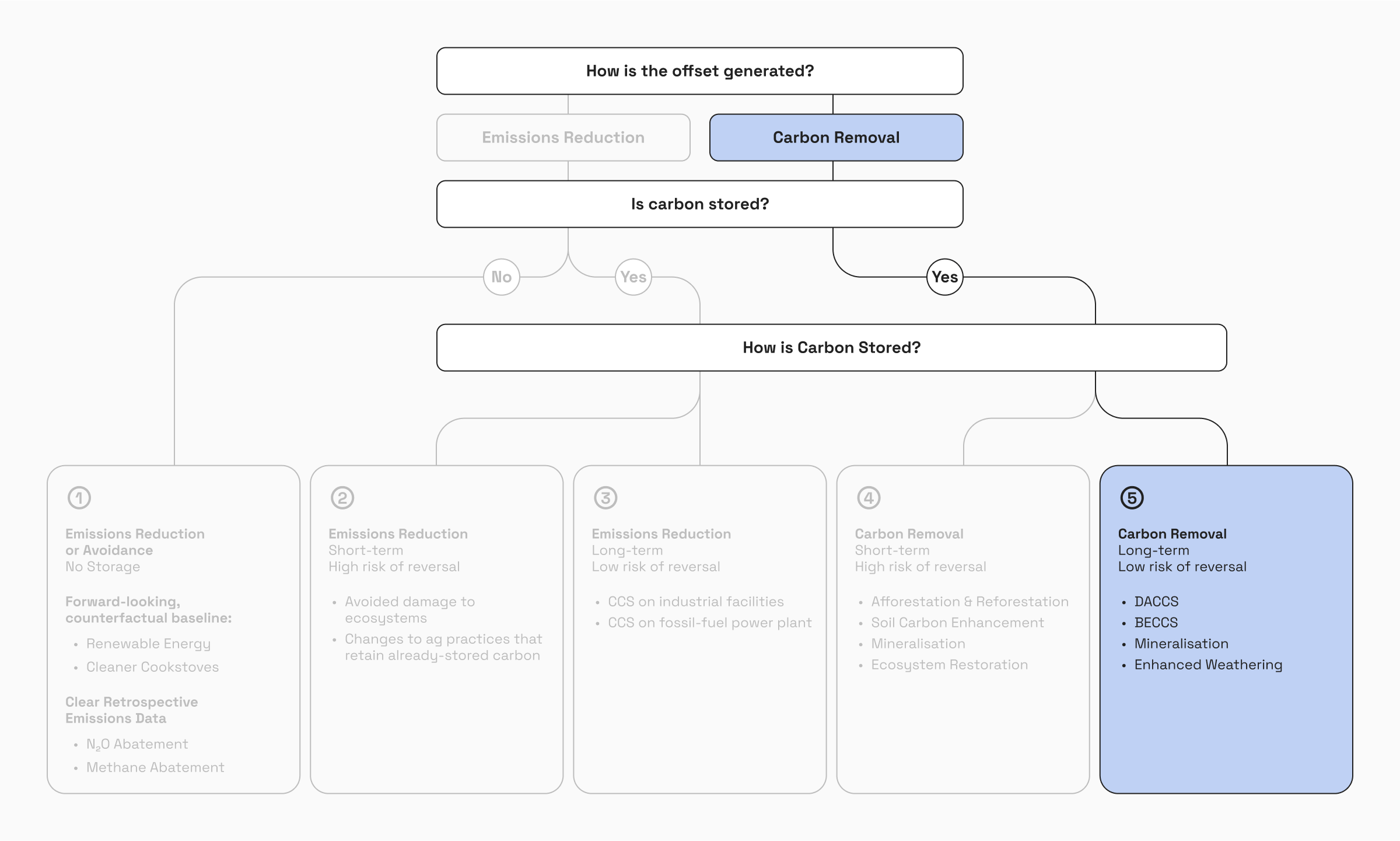

Diagram showing Type 5 from within the Oxford Offsetting Principles – carbon removal with long-term storage

Diagram showing Type 5 from within the Oxford Offsetting Principles – carbon removal with long-term storageAnd what’s holding Direct Air Capture back?

Whilst the potential for scale is what makes Direct Air Capture particularly exciting, it’s also what’s currently holding it back – the technology just doesn’t exist at scale yet.

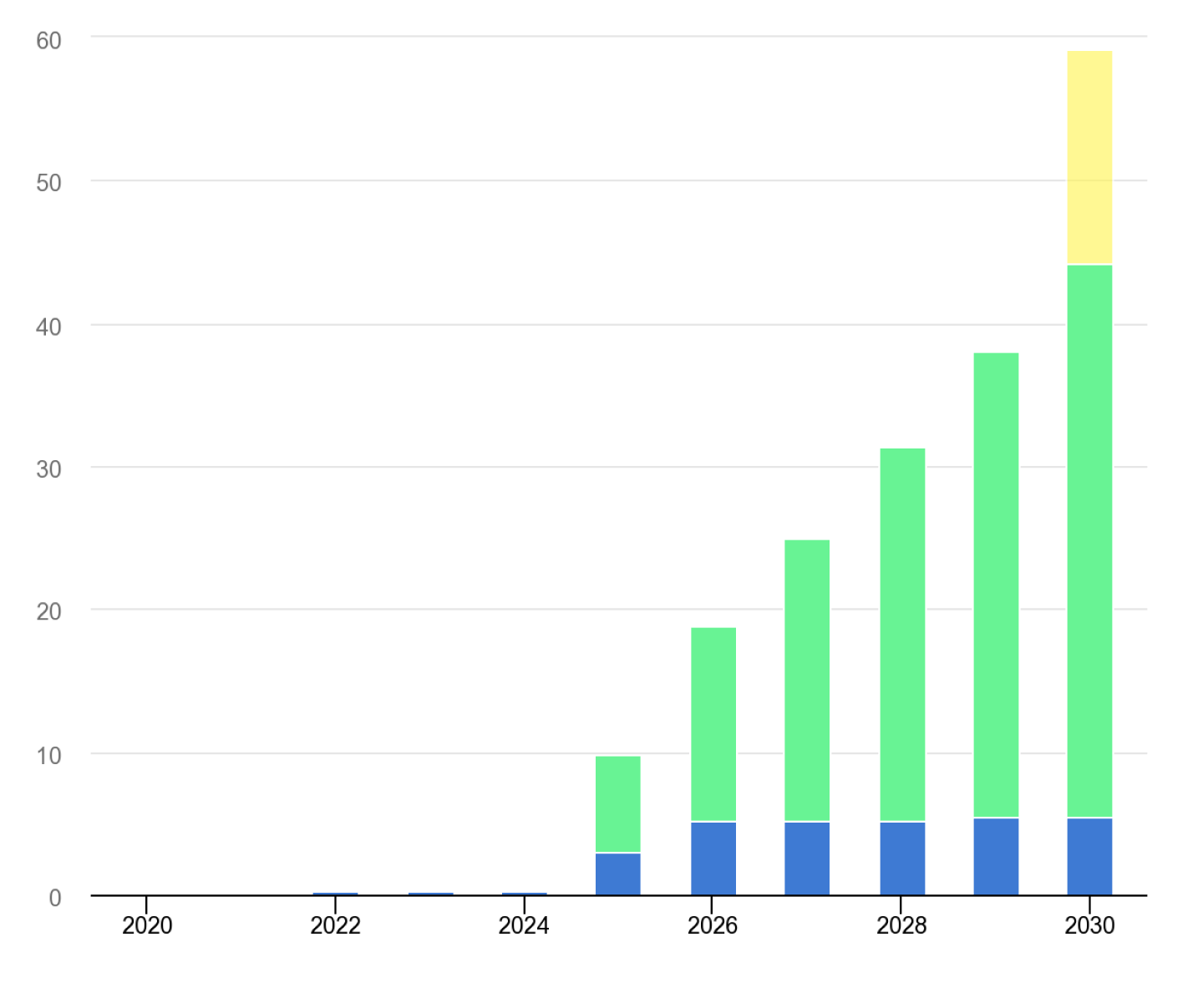

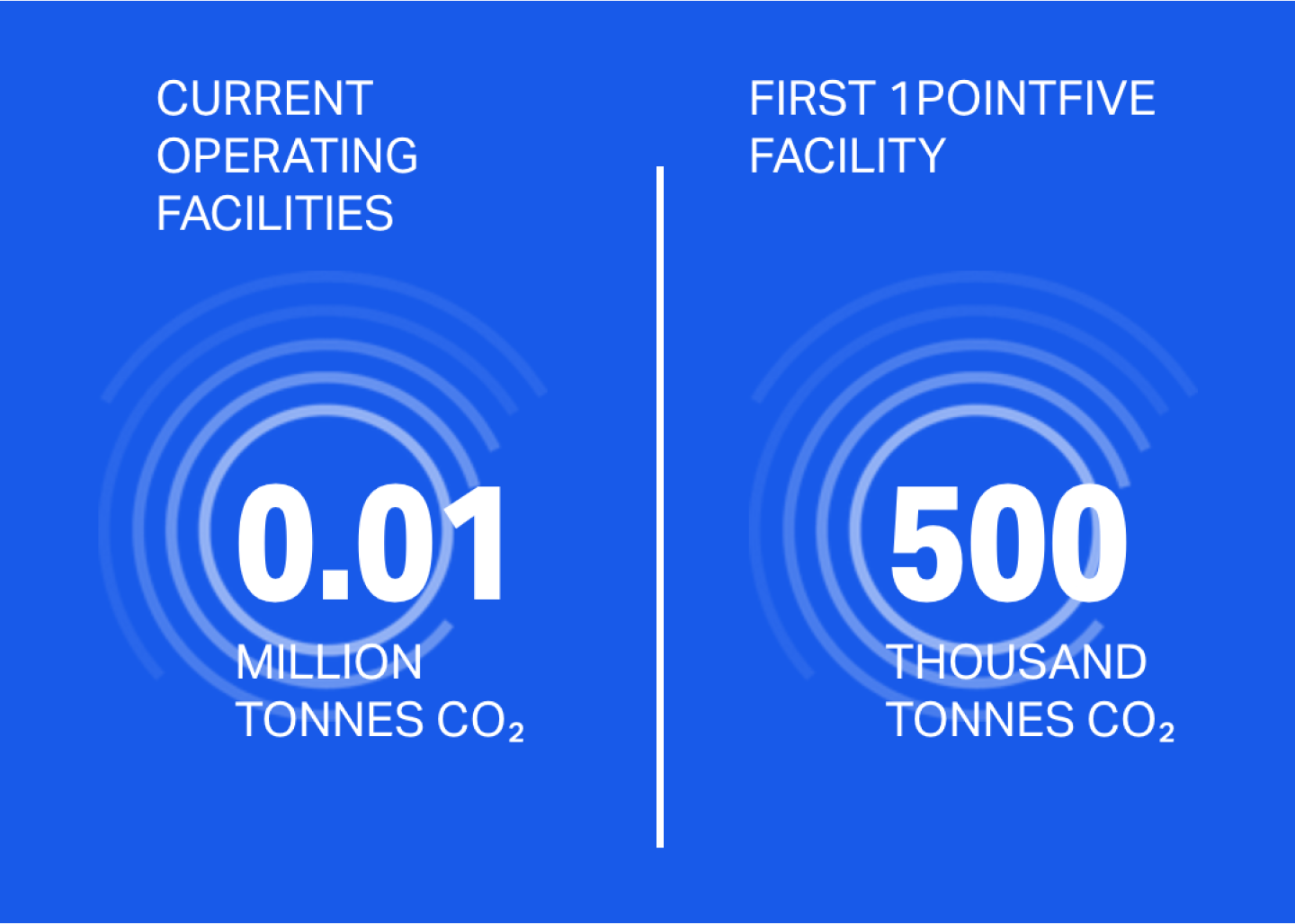

As of 2022, there are currently 19 Direct Air Capture plants in operation globally, with the capacity to capture almost 10,000 tCO2 per year (0.01 megatonne). There are further plants in development, including 1PointFive’s design for a DAC plant that captures 1 megatonne of CO2 every year. But, even with this, we’re still not close to what’s needed – the Net Zero Emissions by 2050 Scenario (NZE) by the International Energy Agency requires 60 megatonnes removed by Direct Air Capture every year, for instance.

IEA, CO2 capture by direct air capture, planned projects and in the Net Zero Scenario, 2020-2030, IEA, Paris https://www.iea.org/data-and-statistics/charts/co2-capture-by-direct-air-capture-planned-projects-and-in-the-net-zero-scenario-2020-2030, IEA. Licence: CC BY 4

IEA, CO2 capture by direct air capture, planned projects and in the Net Zero Scenario, 2020-2030, IEA, Paris https://www.iea.org/data-and-statistics/charts/co2-capture-by-direct-air-capture-planned-projects-and-in-the-net-zero-scenario-2020-2030, IEA. Licence: CC BY 4So, what’s stopping the technology reaching that scale? Current question marks around scaling up Direct Air Capture are:

- Cost: because DAC uses new, innovative technologies, it comes with the need for large injections of cash to pay for materials, research, development etc – and for carbon credits in DAC to reach an affordable price, because right now it’s just too expensive. The aim is that as DAC projects scale, they get down the cost-curve to around $100 per tCO2. There has been some government funding put into DAC, and forward-thinking businesses are buying carbon credits in early-stage DAC projects (such as the Frontier portfolio by Stripe, Shipify, McKinsey et al) – but much more funding is needed.

- Research and development: because there are so few active DAC plants out there, there is a lack of real-world demonstration of the technology – further evidence will be needed to refine the technology and raise confidence in its impact.

- Energy intensivity: the solid and liquid methods for separating CO2 from air that are currently in use use high amounts of energy – research published in Nature Communications (2019) found that if we scaled current DAC methods up to meet climate targets it would use 25% of total global energy supplies by 2100. This means that a) we need renewable energy production to also scale up so that DAC plants can be combined with renewable energy and/or b) research into new techniques for separating CO2 needs to be funded to address this.

Should companies buy carbon credits from Direct Air Capture projects?

If you’re truly committed to making a real difference as an organisation, then we’d definitely recommend buying carbon credits from Direct Air Capture projects.

Why?

Because, as we outlined above, Direct Air Capture could hold the key to permanently removing vast amounts of CO2 from the atmosphere – which is desperately needed to curb climate change. But, to do that DAC needs to scale up quickly, and that requires funding.

And businesses have the ability to provide that funding and enable that potential to be reached through using their revenue to buy carbon credits – it’s one of the most important actions needed today.

But, you do need to be aware of:

- Affordability: carbon credits in Direct Air Capture projects are currently expensive, at around $500 per tonne.

- Availability: because there are a limited number of projects, there is also a limited availability of carbon credits to buy from them.

- When impact occurs: if you buy 1 carbon credit from a DAC project today, you’re paying for 1 tonne of CO2 being removed from the atmosphere, but that removal will likely not take place today – it will take place in the future once the plant is fully operational – so the impact made is not immediate. This means there’s a risk that if the technology or project were to fail, the impact would never occur.

These factors are why we always recommend building a portfolio of projects to buy carbon credits from.

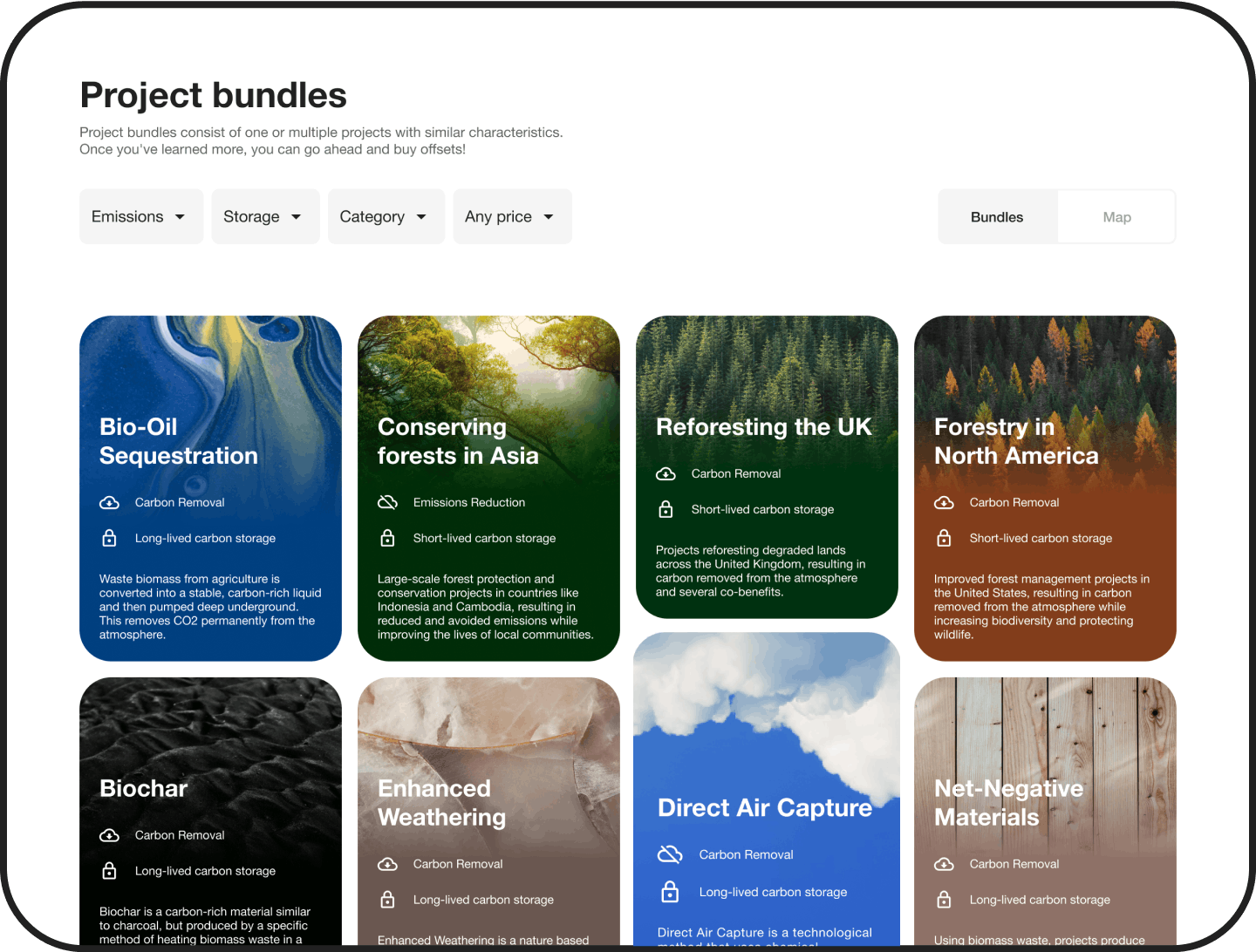

The Lune dashboard, showing carbon project bundles

The Lune dashboard, showing carbon project bundlesA portfolio approach enables you to balance out your company purchases in terms of cost, emissions avoidance vs carbon removal, impact made now vs impact made in the future, established techniques vs innovative new technologies etc – and we especially recommend creating a portfolio aligned with the Oxford Offsetting Principles.

And, of course, if you are considering buying carbon credits from a Direct Air Capture project, you need to be confident that it’s a high-quality, credible carbon project.

We’d suggest taking a look at both 1PointFive and Noya – both trusted, credible projects with different approaches but a shared goal of scaling up the supply of Direct Air Capture to meet climate targets.

1PointFive is making commercial-scale Direct Air Capture a reality

As we’ve seen, for Direct Air Capture to work we need to prove it’s actually possible to scale up and capture vast amounts of carbon dioxide straight from the air around us.

The good news? 1PointFive is working on exactly that – aiming to ramp up Direct Air Capture in a major way.

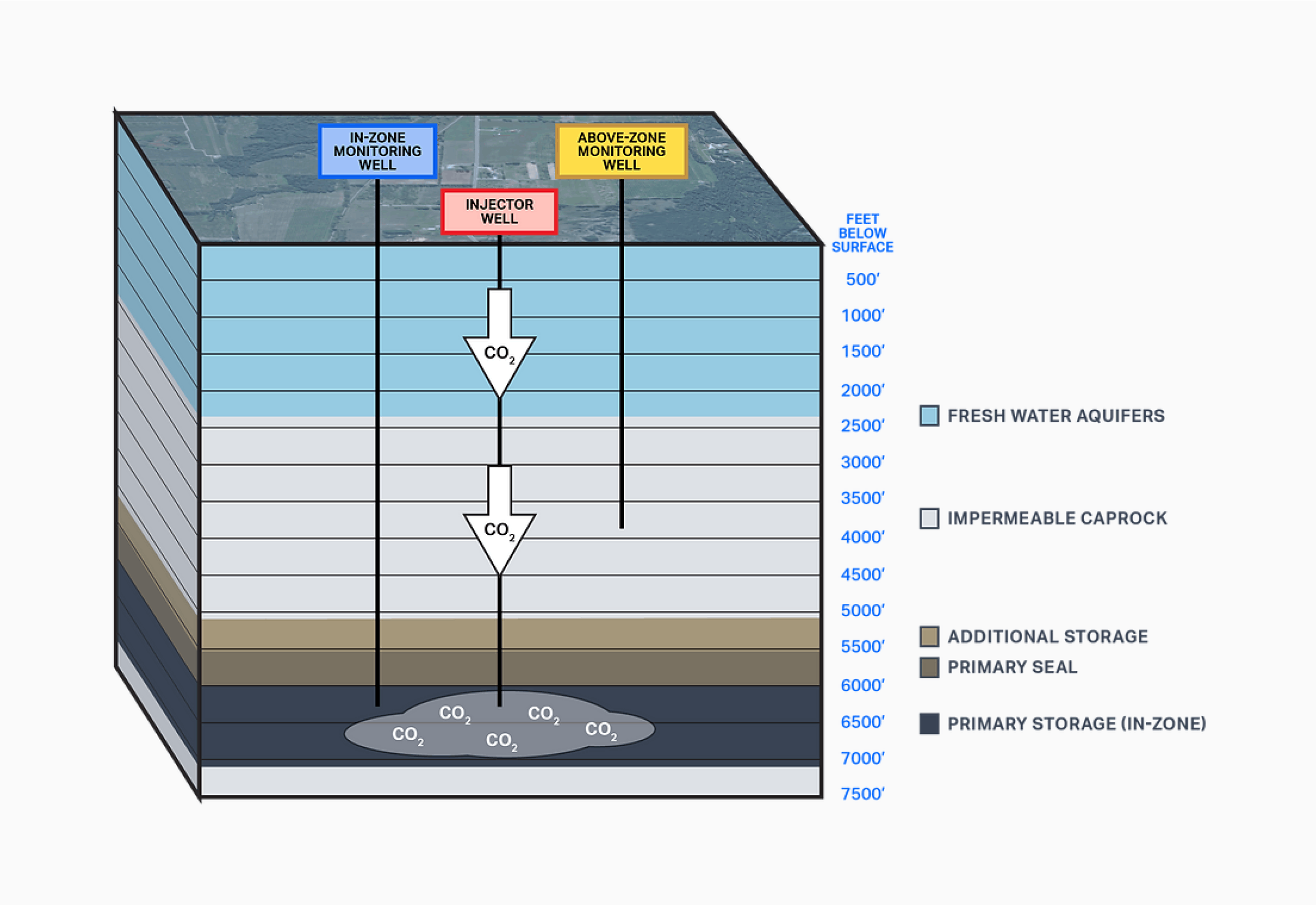

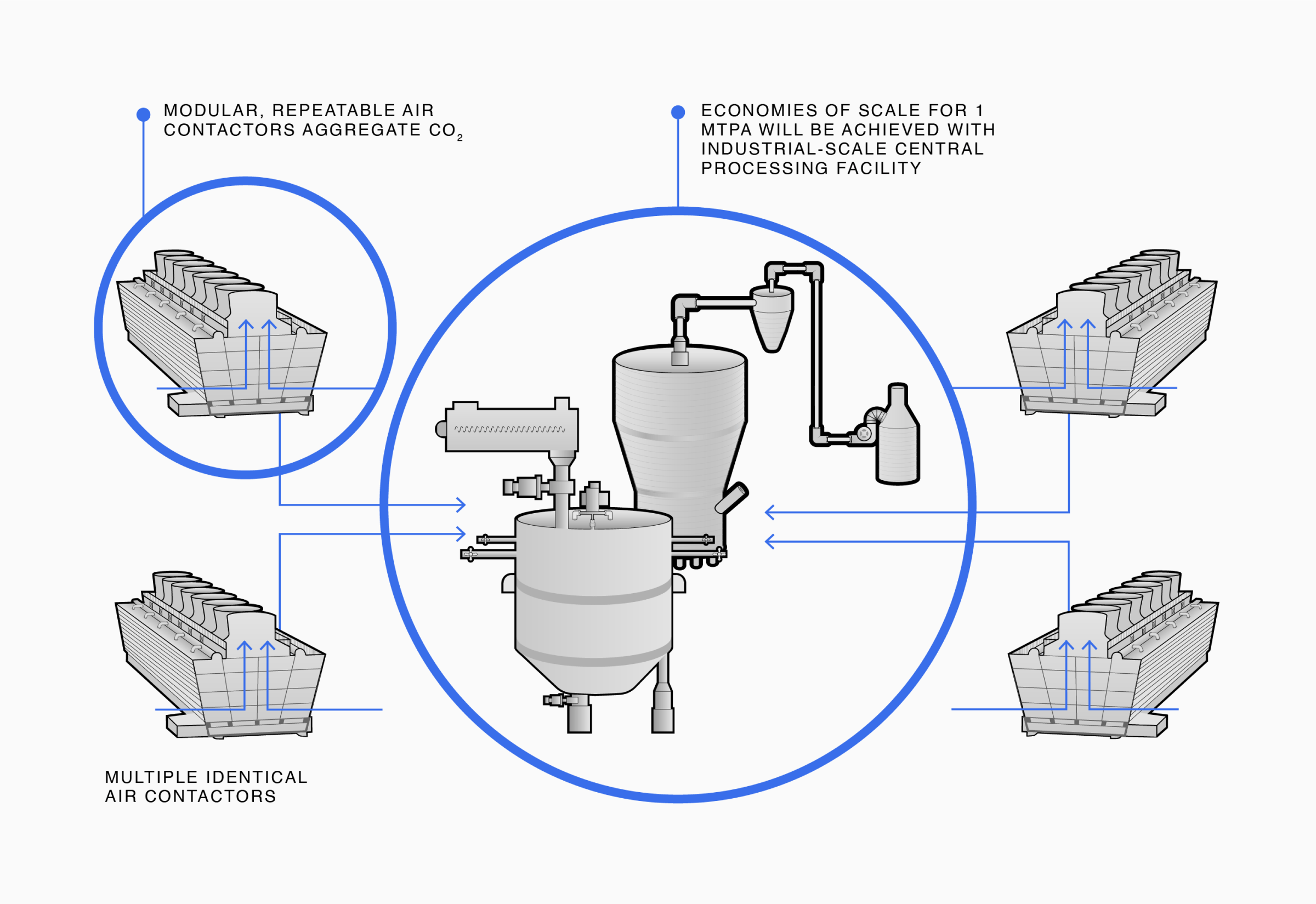

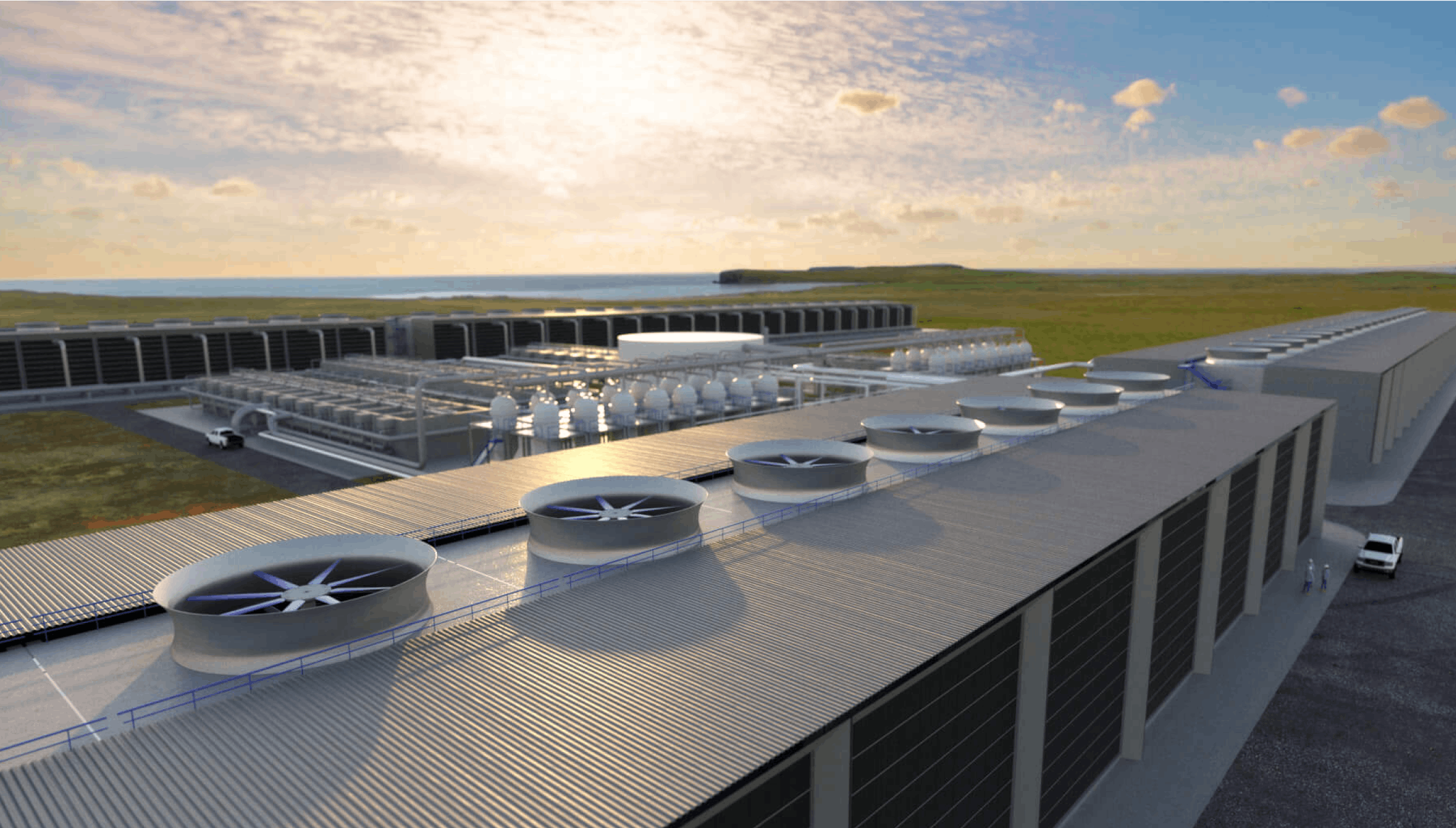

Construction of their first DAC plant in the Permian Basin, USA is currently underway. The design uses arrays of ‘air contactors’ that take in the air and absorb the CO₂, all feeding into one industrial-scale processing facility for increased efficiency – enabling the commercial scale that we need to see in Direct Air Capture.

Credit: 1pointFive

Credit: 1pointFive1PointFive’s DAC plants will be connected to ‘geological sequestration hubs’: sites where the extracted CO₂ can be safely injected deep underground for permanent storage.

1PointFive is planning to develop multiple sequestration sites across the Gulf Coast, including at the King Ranch in South Texas, where 1PointFive has secured enough acreage to enable the potential development of a mega hub with up to 30 DAC plants.

This represents a massive increase in global DAC capacity. The first plant alone aims to remove 500,000 tCO₂ per year, compared to our current total capacity of 10,000 tones per year.

Credit: 1pointFive

Credit: 1pointFiveMarkers of quality in 1PointFive’s project

At Lune we always put quality first to ensure real climate impact is made through the carbon projects in our library.

So what are the markers of quality in 1PointFive’s Direct Air Capture project? Here’s a few of the key ones:

- Proven technology: 1PointFive has partnered with Carbon Engineering, a renowned engineering company who has developed replicable DAC technology with the possibility to reach scale – 1PointFive is enabling this technology to scale up and be commercially available for carbon removal.

- Team of experts: 1PointFive is owned by Occidental, an international energy company now committed to using their existing CO₂ infrastructure and their substantial experience in both carbon management and large-scale project development to find innovative solutions for human-made carbon emissions. As partners in the project, Carbon Engineering also brings technical expertise in DAC technology to the project team.

- Permanent storage: the inclusion of geologic storage sites means that CO₂ will be durably removed from the atmosphere and safely stored – giving the highest possible impact.

- EPA approved sequestration sites: All 1PointFive storage sites will be approved by the Environment Protection Agency (EPA), and will be subject to an ongoing, extensive Monitoring, Reporting and Verification (MRV) program regulated by the EPA.

- Leakage risk mitigations: the high energy use of Direct Air Capture plants is a key concern, resulting in further greenhouse gas emissions and potentially negating the positive impact the projects make (known as leakage). 1PointFive is mitigating the risk of this through powering all their facilities with zero-emissions energy (wind, solar, or natural gas with CCS), using liquid sorbents to extract CO₂ from air – which uses less energy than solid sorbents, and conducting detailed lifecycle assessments of their sites so that their own emissions are removed from measurements to avoid any overestimation of impact.

- Local engagement: Throughout the development of their first DAC plant, the 1PointFive team has been engaging with the local community to better understand their concerns and needs, including meeting with local councils and elected representatives. Currently, there is a large opportunity in low carbon job creation, and 1PointFive is collaborating with local schools and universities to develop the skills needed for the facility to ensure these job openings benefit the local workforce.

Noya is making Direct Air Capture affordable through harnessing existing infrastructure

As we’ve seen, high energy use is one of the main barriers for Direct Air Capture technology currently.

Ensuring close proximity to renewable energy sources (as 1PointFive are doing) is one way to address that. But we also need to find innovative ways to reduce the energy use of DAC in the first place – and Noya is doing just that.

Noya was initially exploring how to retrofit existing cooling towers with Direct Air Capture technology. Part of this exploration included how to reduce energy consumption, so that the technology could use the energy sources already set up for existing buildings.

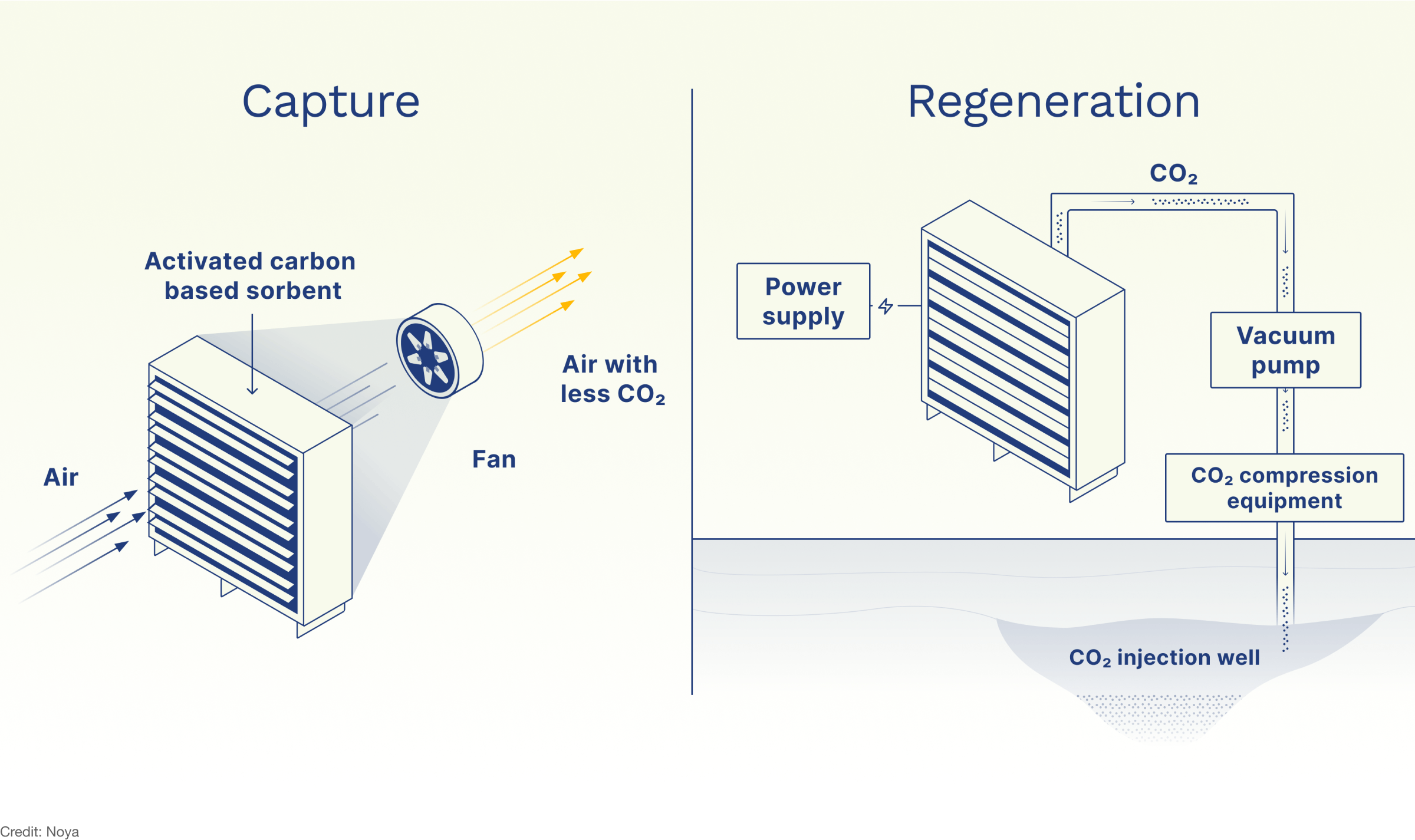

Now, Noya has shifted focus to standalone DAC units co-located with renewable energy and geological storage for permanent carbon removal – but still using their methodology for reduced energy use.

Noya’s DAC method uses activated carbon monoliths coated with the CO₂ adsorbing chemicals to separate CO₂ from air. Increased temperatures are then needed to ‘desorb’ the CO₂ from the monolith to give a stream of pure CO₂ – the energy intensive part of DAC. But, because the activated carbon monoliths are electrically conductive, electricity can be applied directly to the monolith to provide heat. This allows for rapid heating and minimises any energy lost in the process, resulting in significantly lower energy use.

Credit: Noya

Credit: NoyaMarkers of quality in Noya’s project

It’s early days for Noya’s approach, but signs of quality include:

- Innovative approach and scientific experts: it’s clear that Noya has been innovatively exploring ways to break down existing DAC barriers, and their in-house team of experts ensures their work is always scientifically robust – including both of the company’s co-founders, who come from backgrounds in engineering themselves.

- Permanent storage: ensuring their sites are suitable for geological storage means that the carbon they remove will be out of the atmosphere for good.

- Rigorous MRV: the team is currently developing their rigorous process for measurement, monitoring, and verification (MRV) which will ensure that their DAC sites are as impactful as possible. Particularly, they’re focusing on how to share this information and bring accountability into the process.

- Transparency: when Noya shifted their focus away from retrofitting cooling towers, they deliberately chose to share it publicly – the reasons for it and their approach going forward – to increase transparency about their project. The team intends to keep this transparency and communication open throughout, helping to build trust and accountability in the broader carbon removal industry.

Credit: Noya

Credit: NoyaYour next steps...

To buy carbon credits from 1PointFive or explore our full library of high-quality carbon projects, log-in or sign-up to the Lune dashboard to get started.

Or, if you’re interested in building an impactful offsetting portfolio that includes Direct Air Capture but want to discuss the best way to go about this for your company, get in touch with our team first – we’d love to chat.

Readers also liked

Readers also liked

Subscribe for emissions intelligence insights

Get the latest updates in the world of carbon tracking, accounting, reporting, and offsetting direct to your inbox.